Manufacturing

All "thorough control" is for quality improvement.

The Quality Control Department conducts all process controls,

from cultivation control of raw materials to product control.

Daily, careful, and reliable analytical work is an extremely

important role in protecting the quality of products.

Therefore, we are working with great care.

Health management inside and outside the plant and

health guidance for employees are also one of the important daily tasks.

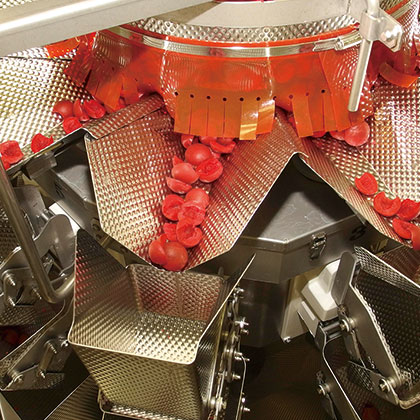

Sorting and processing

We will start pickling at the harvest time of the plum (from the end of May to the beginning of June). If salt is given abruptly, it will cause wrinkles. Therefore, it is important to add salt gradually to the specified salt level. Since the temperature and humidity are high during this period, we are carefully managing raw materials. It is a very important process to determine the good or bad quality of kali plum.

Manufacturing power produced by skilled personnel

Procurement and seasoning

We pay close attention to weighing and agitating operations because it is important to keep

the seasoning constant at all times in the preparation process, where the "flavor" of the

product depends on.

Inspection and shipment

Before filling, the product is inspected visually to improve quality. "Manufacturing

capabilities" created by experts are our major strengths. After final inspection of the finished

product, it will be packaged and shipped.

During the busy season, shipments will also increase, requiring accurate and speedy

processing.